As one of the benchmark enterprises in Ningbo metal products industry, Ningbo Lisan Stainless Steel Products Co., LTD. (hereinafter referred to as "Xinlisan") has been focusing on the research and development and production of non-standard parts, forging parts and special-shaped parts since its establishment in 1980, taking technological innovation and quality improvement as the core.Gradually develop into an annual production capacity of 6000 tons, products are exported to Europe, America, Australia and other global markets of international enterprises.

1.Innovation-driven, Creating "Hidden Champions" in the field of trailer parts

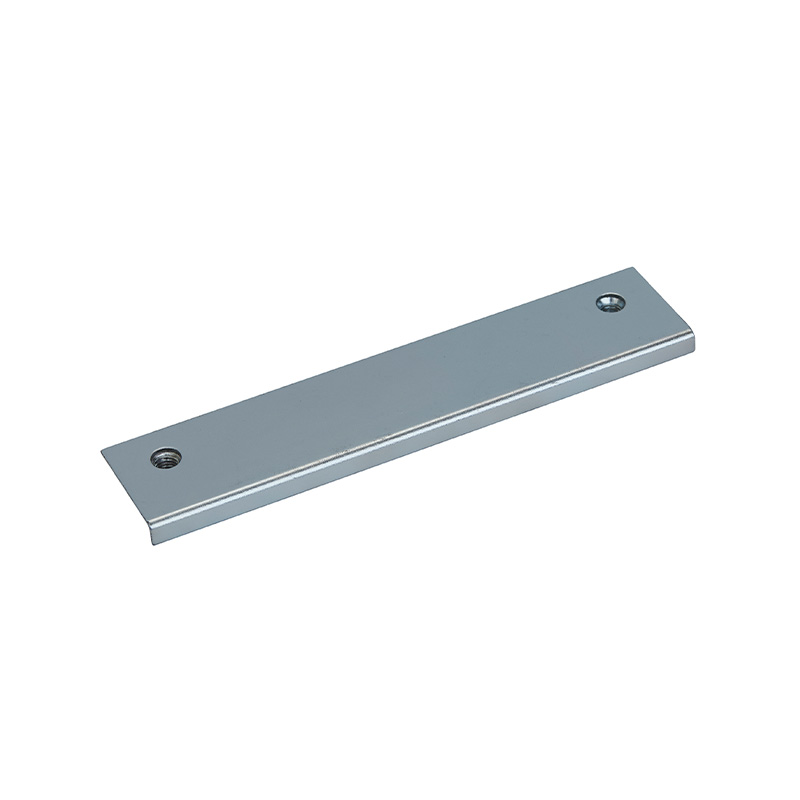

Relying on the geographical advantage of Ningbo Daxie Xiexi Industrial Zone, Lishan is close to Ningbo Port and has efficient international logistics conditions.The company started with traditional businesses such as metal wire drawing and fasteners in the early days. In recent years, through independent research and development, it has successfully expanded a series of Trailer accessories products, including Hitch balls, Ball mounts, trailer couplers, etc. 100% of the products are exported.It holds an important share in markets such as North America and Australia.

To meet the high standards of the international market, Xinli SAN has introduced CAD/CAM computer-aided design and manufacturing technology and has fully passed the ISO9001:2000 quality management system certification, ensuring the standardization and reliability of the entire product process from design to production.In addition, the company continuously optimizes its production process, enhances efficiency through automated equipment, and has a factory area of 13,000 square meters. The proportion of technical management personnel is nearly 8%, forming a professional technical team.

2.Quality serves as the foundation, and standardization leads the industry's upgrade

Under the strategic background of "high standards leading high-quality development" in Ningbo City, Lishan actively responds to the regional standardization construction.The company not only participates in formulating industry technical standards, but also enhances production accuracy through digital and intelligent transformation. For instance, it uses mechanical arms to complete quality inspection, reducing raw material waste by over 20%, and achieving the dual goals of green manufacturing and efficient production.

The "Zhejiang Manufacturing" group standard development work promoted by the Market Supervision and Administration Bureau of Zhenhai District in recent years has also provided a technical benchmarking direction for third-class enterprises.For instance, the breakthroughs made by peer enterprises such as Ningbo Jingzuan Technology in the field of standardization (such as the formulation of the "Optical-grade Large Single Crystal Diamond" standard) have provided a reference for the collaborative innovation of the industrial chain for Lishan.

3.With a global layout, the export business is steadily advancing

Despite the challenges posed by global economic and trade frictions, SONY Ericsson's export business has continued to grow thanks to its stable product quality and flexible supply chain management.The company further expands the markets along the "Belt and Road" through self-operated and agency import and export business, and relies on the hub advantages of Ningbo Port to optimize logistics costs.

t is worth mentioning that in recent years, Ningbo City has been vigorously promoting the export of the "new three items" (new energy vehicles, photovoltaic power, and lithium batteries). Although Xinli SAN has not ventured into these fields, its resilient development in traditional manufacturing has provided strong support for the stable growth of regional foreign trade.According to statistics, in 2024, nearly 85% of foreign trade enterprises in Ningbo will simultaneously engage in domestic sales. Meanwhile, Xinli SAN adheres to the "specialized, refined, distinctive and innovative" route, focusing on differentiated competition in the international market.

4.Future Outlook: Moving towards high-end and green development

Lishan plans to further promote the serialization, standardization and specialization of its products, and develop new types of products that meet the needs of different customers.Meanwhile, the company actively responds to the green manufacturing policy of Ningbo City, explores the application of low-carbon technologies such as rooftop photovoltaic power generation, in order to reduce energy consumption and enhance sustainable development capabilities.

The "Value-Added Reform of Intellectual Property Services" and the "Employee Innovation and Efficiency Project" recently proposed by the Market Supervision and Administration Bureau of Zhenhai District have also provided policy support for Lishan.For instance, through financial tools such as "industrial reform loans", enterprises can obtain a maximum loan amount of 50 million yuan, which is used for technological upgrading and talent introduction, further consolidating their competitiveness in the global industrial chain.

The growth journey of Ningbo Lisan Stainless Steel Products Co., Ltd. from a local metal processing factory to an international supplier of trailer parts is a microcosm of the transformation and upgrading of traditional manufacturing industries in Ningbo. Driven by the dual wheels of "high standards" and "new quality productivity", Lishan is taking innovation as its wing to write a new chapter of "Made in China" going global.

English

English 中文简体

中文简体